SHENYI AUTOMATIC CONTROLLING VALVE APPARATUS CO.,LTD.

Services We Offer:Pneumatic actuators,Control valves,Electric control valve,Self-reliance control valve,Pneumatic ball valve,Electric Ball Valve,Pneumatic butterfly valve,Electric butterfly valve..

Current: ShenYi >> Product >> Valve >> Gate valve >> Pneumatic&Manul wedge gate valve

Pneumatic&Manul wedge gate valve

Messages If you want any further detail data and drawing,please contact us.Tel:86-577-67968697 Fax:86-577-67968699

♦ Overview

Z6S41T- 10, Z6S41T-16, Z6S41T-25, Z6S41T-40, Z6S41T-64 series pneumatic-manual wedge type gate valve if our company's new shaped product. For the advance technology, reliable function, convenient operation switch maintenance, it is widely used as pipeline on-off equipment for transmit gas, liquid medium in the section of petroleum industry, chemical industry, metallurgy industry, electric power, sea transportation, etc.

This is a kind of low support and bare rod gate valve with pneumatic actuator( double-cylinder with extrusion actuator) and manual protection actuator(self-lock and pneumatic manual switch equipment). For the double-cylinder structure, its lifting ability is one time larger than the single-cylinder type pneumatic gate valve. This can basically resolve the defect of some board of single pneumatic gate valve the hard wedged in the valve body and can't open. For the extrusion actuator, it effectively reduced the friction that caused by the thrust between the sealing face of valve board and valve body when the piston moving downwards. And without the phenomenon of locking.

In order to help the users to carry out operation automatization, besides the series of products, we can also supply cylinders including support to help the user to rebuild the various manual gate valve in hand. The gate valve will be a two cylinder pneumatic& manual type that equip with the cylinder on the body cap.

♦ Principle and features

This series of product takes 0.4~0.6MPa(face pressure) pure compressed air as operation motor to push the piston, then bring the gate board move vertical to the liquid and carry out the purpose of open and close the valve.

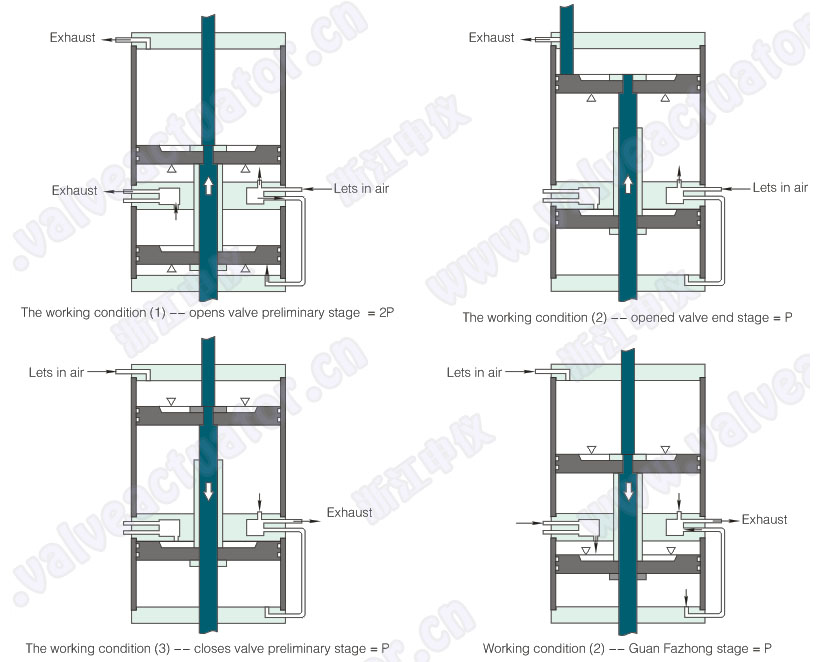

The operation principle of double-floor cylinder and extrusion actuator according to the four phases of gate valve's work is divided as follows:

1、the fore-phase when opening the gate valve: the piston of top floor cylinder(short for top piston) and the piston of lower-floor(short for down piston) under stress at the same time and push the stem, take two times lifting strength more than single cylinder to overcome the max static friction between the board sealing face and body face, bring the gate board lifting then. From the top cylinder's down air-room the compressed air go through the assigned alleyway which set on the clapboard and go across the connecting piper, then reach t o down cylinder's down air-room and thrust top and down piston work at the same time. the air in the top air-room of down cylinder go through the other special alleyway that set in the clapboard and expelled from the cylinder flowingly.

2、the after-phase when opening the gate valve: open the gate board and the down piston will move to the up die point, by the drive of the top piston, it lifting continuously and finally to the wide open position.

3、the fore-phase when close the gate valve: under the drive of top piston, the board away from the wide open position and start to decline.

4、the after-phase when close the gate valve: when the top piston touch the male tap of down piston and drive the down piston declining continuously together, the top piston reduced the speed obviously, because of the obstruction at the inlet air alleyway of top air-room and the discharge alleyway of the down air-room in the down cylinder, then the gate board to the wide close position. Ease the thrust when the gate board down moving, the valve self-closed. In this case, the board won't wedged too tight, protect the sealing face and without damage from fierce thrust.

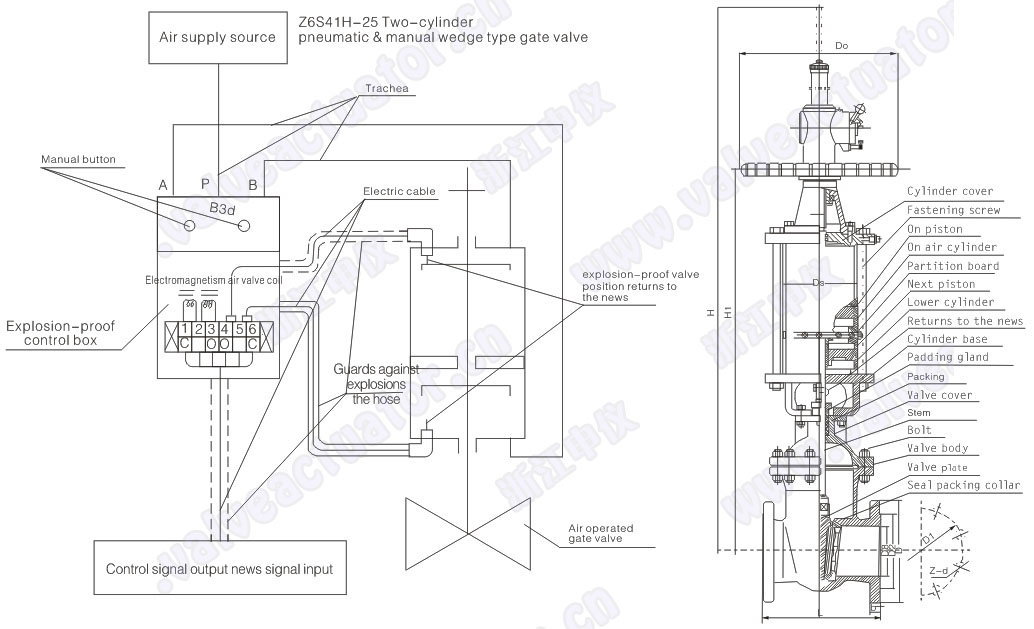

♦ Schematic drawing

Flexible and reliable pneumatic manual switch actuator that equipped on the top of cylinder cap, at any position in the process of open and close can rotate the operating handle conveniently and directly switch from pneumatic to manual or from manual to pneumatic operating way. the handle uses knock lock way self-lock design for lock the handle, reliable and steady. When the solenoid valve and its control current or wind supply system fails, it can immediately switch to the manual operation status without any assisting tool, this ensure the normal course of circuit and avoid the accident. Meanwhile, before the automatic system unfinished this series gate valve can reliably to be used as manual gate valve with flexible movement.

The valve closing time is adjustable, and with the extrusion on the clapboard, it can regulate the closing time in certain range.Can be equipped with acceptor

This kind of valve can be equipped with electric or pneumatic acceptor for sending the message of on-off situation of valve. Therefore, carry out the long-distance control, central control, and auto-control with the valve.

The cylinder of this valve made from seamless steel pipe, the inner face is polished and finished with anti-corrosion hard chrome-plating. It has the advantages of low-friction, anti-corrosion,, high hard, long service life, etc.

The seal ring in the cylinder uses NBR for reliable sealing function and convenient replace.

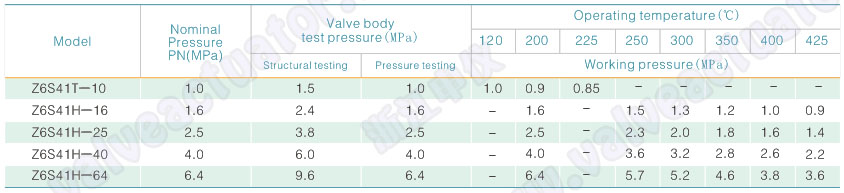

♦ Valve body performance

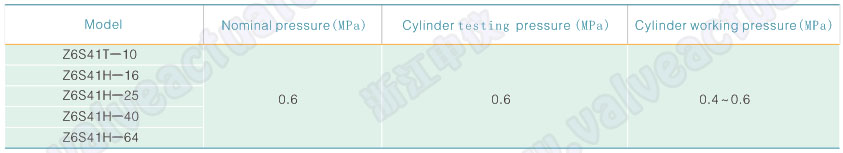

♦ Cylinder performance

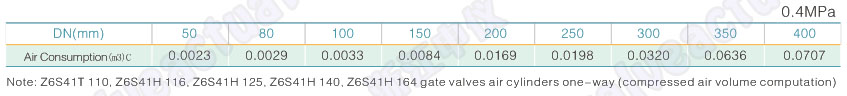

♦ Purification stored air pressure

♦ Structure, material and operating instructions

Structure, material, and usage introduction

1.This valve is made up of valve body, cap, board, stem, seal ring, double-flour cylinder ,piston, piston level, clapboard with cushion actuator, manual actuator, pneumatic-manual switch equipment and cap stuffing box equipment, etc.

2.When the head piston travel to the top of the stroke will prop up the head-acceptor and make it send signal out; otherwise when the down piston travel to the bottom of the stroke will press the bottom acceptor and send signal as the on-off message of gate valve appears on the simulating instrument board of central operation room.

3.the lifting and dropping of protruding indicating level on the top of handle wheel marks the the board of the valve in the situation of lifting or dropping. When close the gate valve, the protruding indicating level will locate at the lowest position; otherwise, will in the highest position with the wide opening. This is the field indication for valve's on-off situation.

4.There equipped with pneumatic& manual equipment on the top of cylinder cap. To clockwise rotate the switch handle to the pneumatic A knock hole@ to locate, the gate valve will be in the pneumatic operation status; on the contrary, with anti-clockwise will go on manual operation. The switch direction of handle with angle gear is opposite. The rotary direction of handle wheel is the same as common manual valve, namely, clockwise is closed, anti-clockwise is open. The switch direction of

handle with angle gear is opposite.

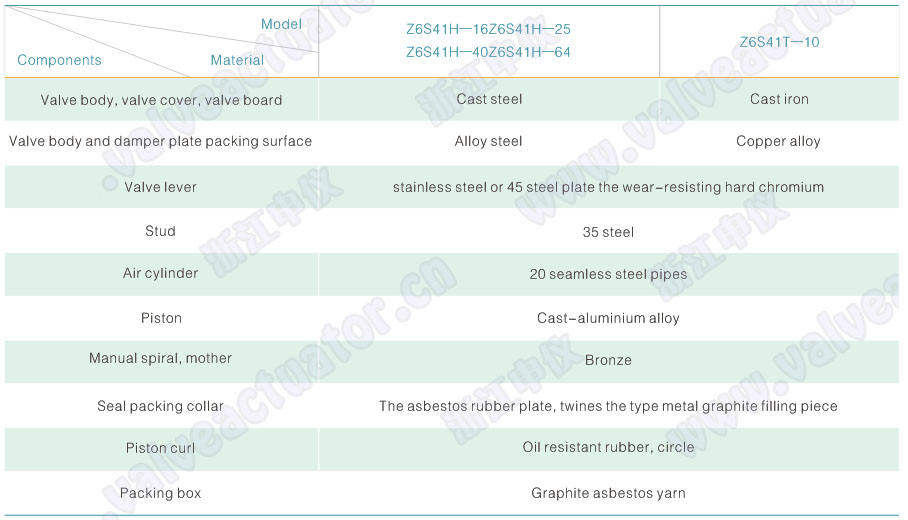

5.Main spare part material (show in the chart as follow)

♦ Systems control schematic diagram

- · Actuator >> Pneumatic

- · Actuator >> Hydraulic

- · Actuator >> Electric

- · Actuator >> Manual

- · Valve >> Ball Valve

- · Valve >> Butterfly valve

- · Vavle >> Globe valve

- · Valve >> Gate valve

- · Valve >> Control valve

- · Valve >> Solenoid valve

- · Valve >> Angle seat

- · Valve >> Shuttle valve

- · Vavle >> Diaphragm valve

- · Valve >> Tube Pinch Valve

- · Valve >> Oxygen valve

- · Fittings >> Reversing solenoid

- · Fittings >> Positioner

- · Fittings >> Limit switch

- · Fittings >> Air supply parts

- · Fittings >> Mounting Bracket

- · Fittings >> Others

Contact Us:

shenyiactuator@hotmail.comLinks: sypv [Chinese]Pneumatic butterfly valvePneumatic ball valvePneumatic actuator